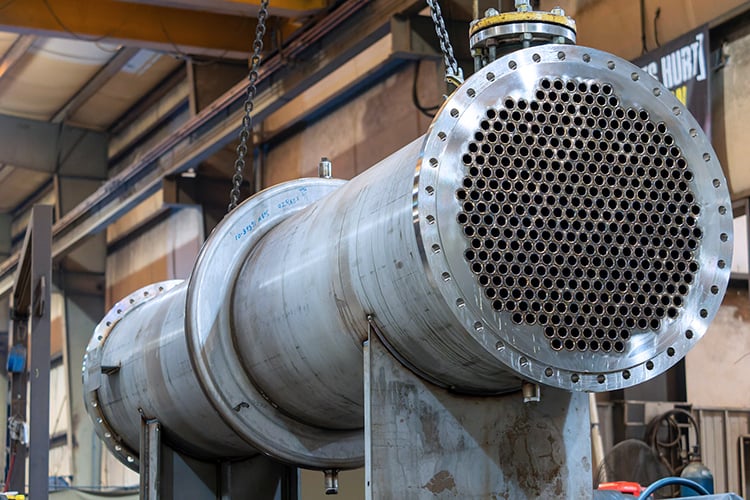

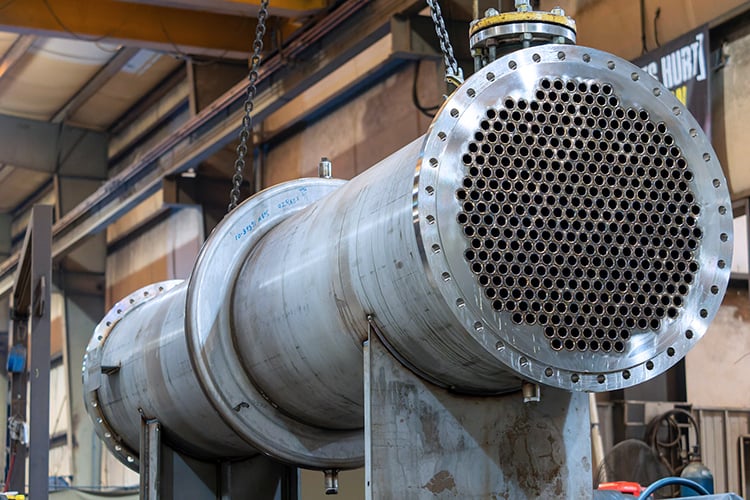

Tritorc offers specialized retubing solutions for heat exchangers, condensers, chillers, boilers, and fin-fan coolers. Our complete in-house retubing systems and experienced engineering team ensure seamless execution—whether on-site or in workshop conditions.

With ASME- and TEMA-compliant methods, we restore full thermal efficiency, extend asset life, and reduce unplanned shutdowns.