Low Profile Ratchet, Hex. Type Hydraulic Torque Wrenches — THL Series

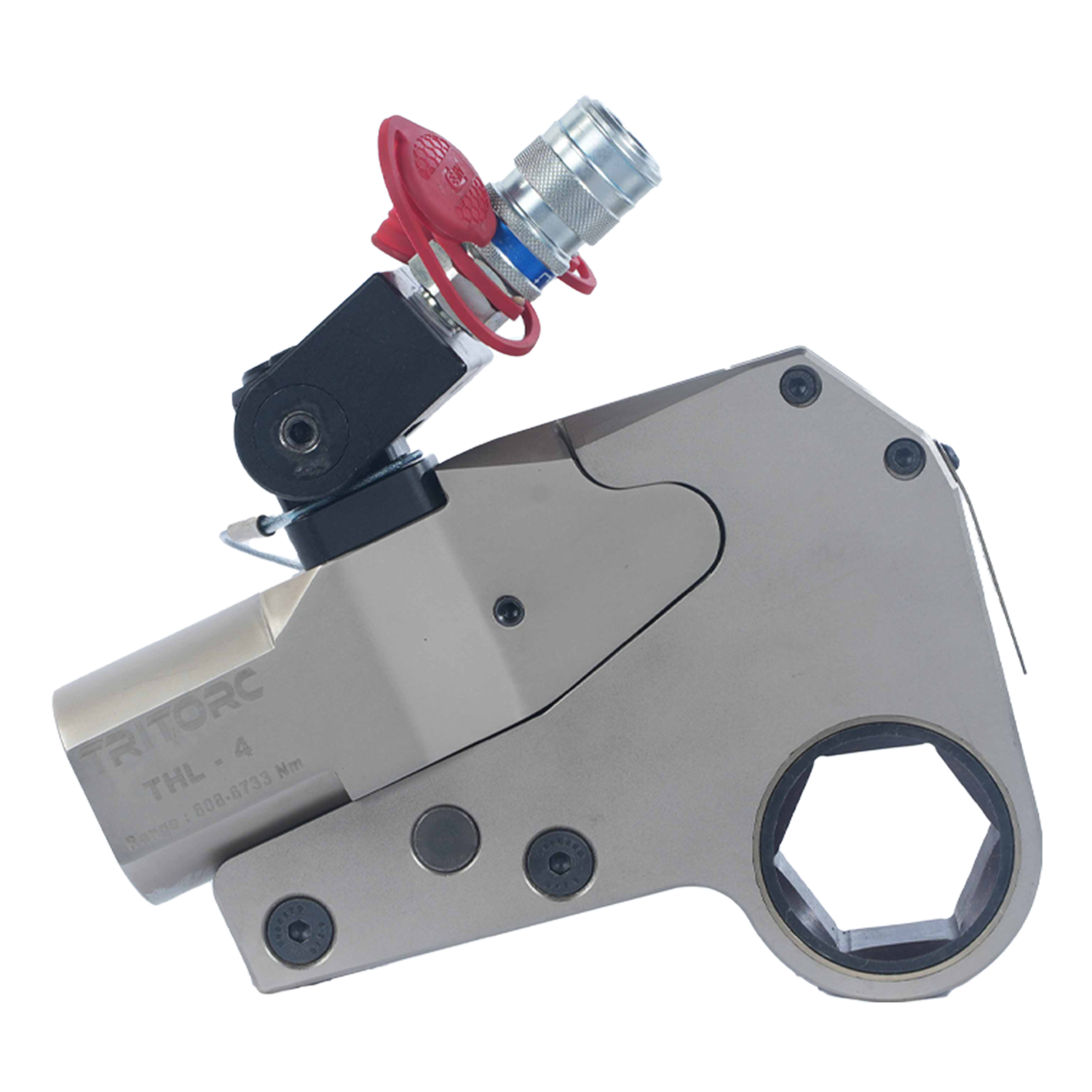

At Tritorc, we recognize that your bolting requirements demand more than just torque delivery; you need reliability, precision, and access in the tightest industrial spaces. The THL Series Low Profile He. Drive Hydraulic Torque Wrench is engineered to directly address these challenges and deliver operational improvements to your workflow.

- Adapts interchangeable hex-links for versatile bolting, enabling quick link swaps to handle different bolt sizes and speed up operations.

- Access tight or confined spaces with a small nose radius, enhancing reach, safety, and bolting efficiency.

- Enables smooth and multi-directional handling of wrench in confined areas, through our 360×180° swivel design.

- Prevents high-pressure leaks that often disrupt work and raise safety concerns through our leak-resistant seal system

- Automatic rod engagement eliminates backlash, ensuring precise torque delivery, smoother operation, and enhanced safety during critical bolting.

- Incorporates a finer-tooth ratchet pawl mechanism for effective engagement, delivering smoother, more accurate torqueing and enhanced operator control.

- Maximum torque up to 53,512 Nm.

- Handles 19 to 175 mm Bolt Sizes.

Low Profile Ratchet, Hex. Type Hydraulic Torque Wrenches — THL Series

At Tritorc, we recognize that your bolting requirements demand more than just torque delivery; you need reliability, precision, and access in the tightest industrial spaces. The THL Series Low Profile He. Drive Hydraulic Torque Wrench is engineered to directly address these challenges and deliver operational improvements to your workflow.

- Adapts interchangeable hex-links for versatile bolting, enabling quick link swaps to handle different bolt sizes and speed up operations.

- Access tight or confined spaces with a small nose radius, enhancing reach, safety, and bolting efficiency.

- Enables smooth and multi-directional handling of wrench in confined areas, through our 360×180° swivel design.

- Prevents high-pressure leaks that often disrupt work and raise safety concerns through our leak-resistant seal system

- Automatic rod engagement eliminates backlash, ensuring precise torque delivery, smoother operation, and enhanced safety during critical bolting.

- Incorporates a finer-tooth ratchet pawl mechanism for effective engagement, delivering smoother, more accurate torqueing and enhanced operator control.

- Maximum torque up to 53,512 Nm.

- Handles 19 to 175 mm Bolt Sizes.

Why Use Tritorc's Low Profile Ratchet, Hex. Type Hydraulic Torque Wrenches — THL Series

Chrome-Plated Piston

Hard chrome-plated piston improves wear resistance, maintains smooth seal interaction, and protects cylinder integrity. Delivering superior abrasion resistance, reduces friction, and significantly extends maintenance intervals of our hydraulic torque wrenches for reliable performance in demanding bolting operations.

THL Series

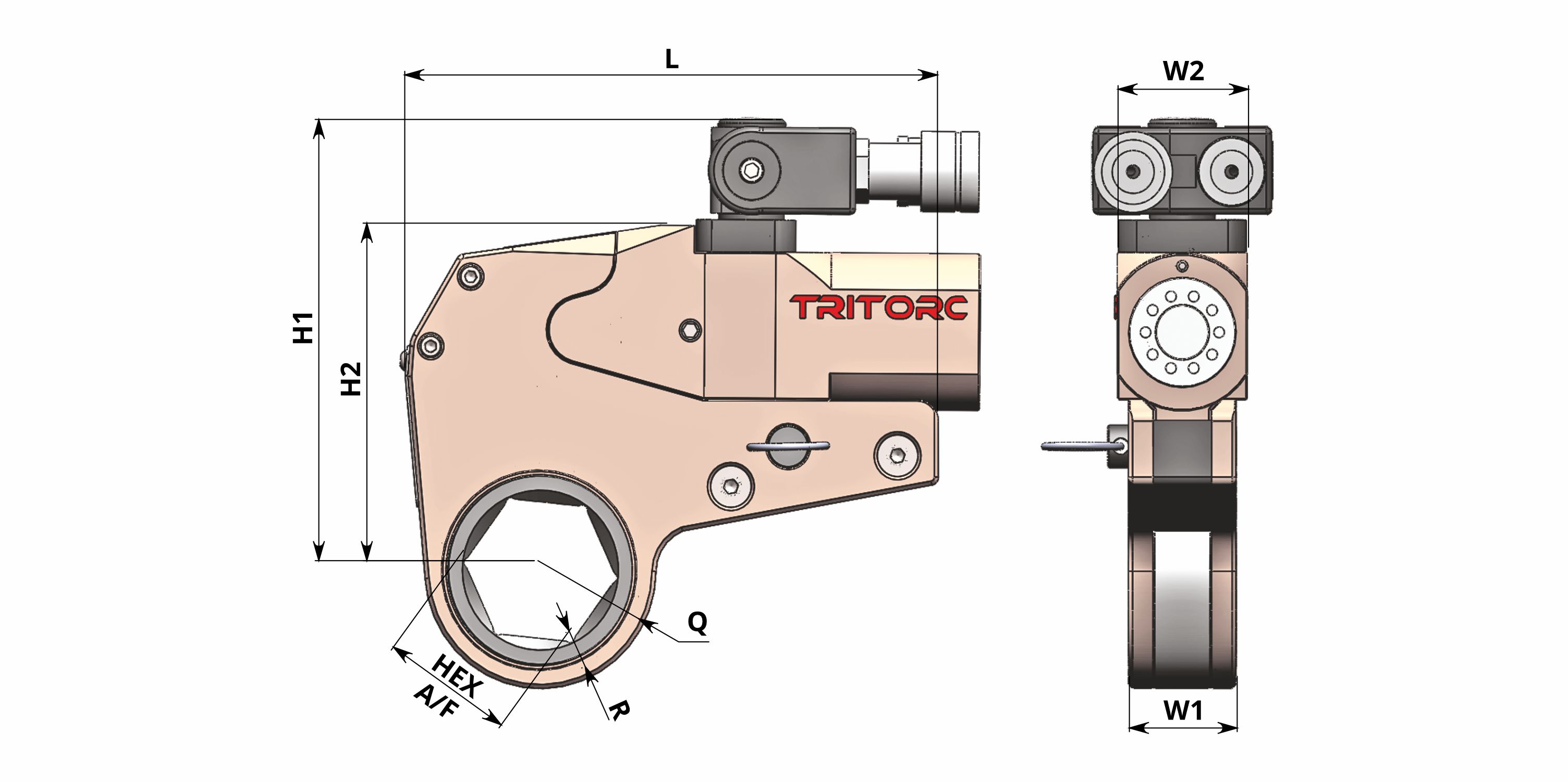

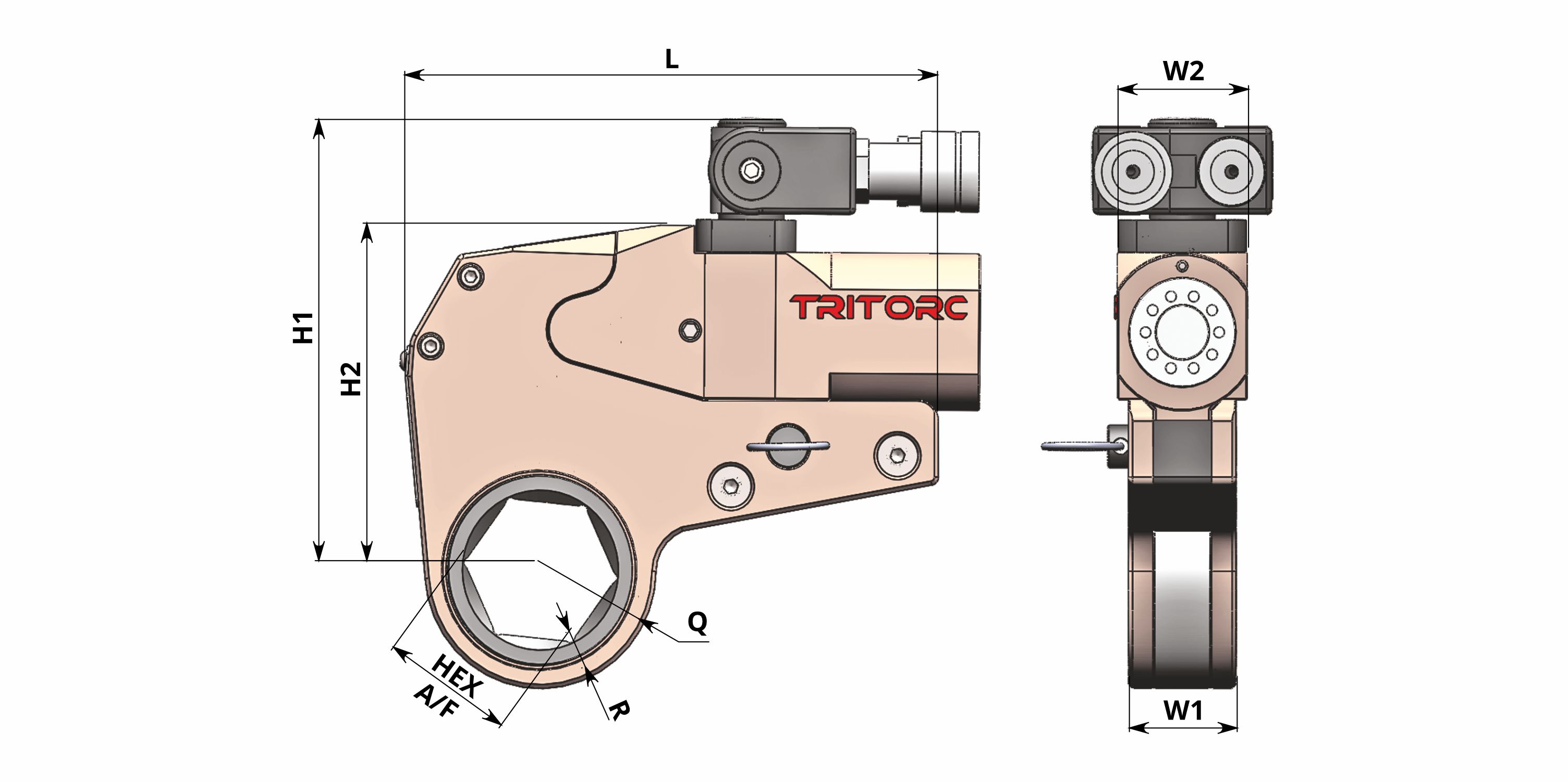

Tool Specifications

Professional torque tools for industrial applications. Select a model to view detailed specifications and technical drawings with precise measurements.

33 to 56 mm

57 to 80 mm

Dimensions

Dimensions

Hex Range

Hex Range

More Products

THL Series accessories are precision-engineered to expand tool adaptability, accuracy, and performance in space-restricted and complex bolting environments. Designed for seamless compatibility, these components ensure optimal fastener engagement, safe torque reaction, and a broader application range for our torque wrenches.

From interchangeable hex-links and drive adapters to specialized reaction supports, each accessory empowers the torque wrench to work effectively where standard configurations cannot — delivering high-accuracy, high-load torquing across critical industrial applications.

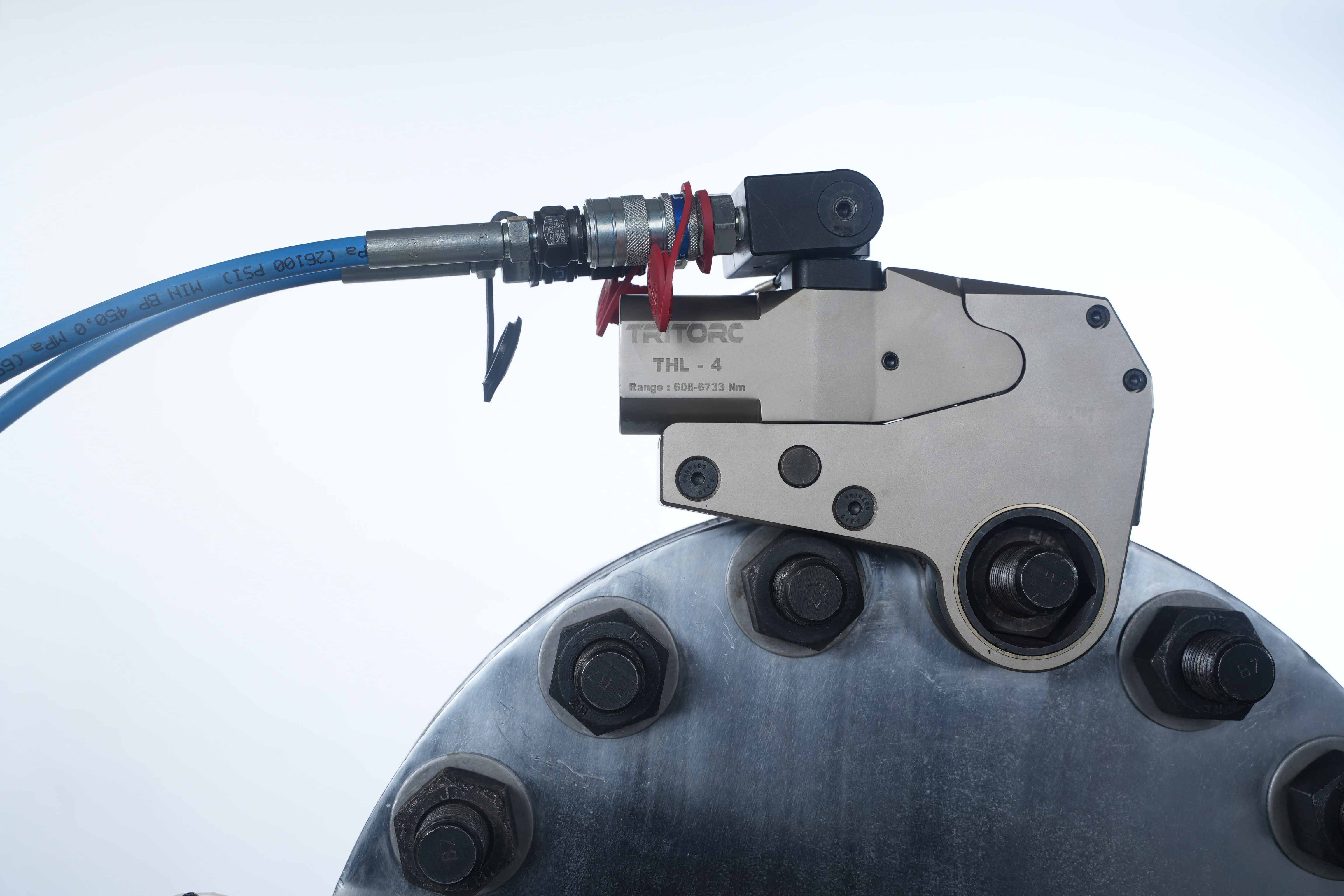

Oil & Gas (Up-/Mid-/Down-stream)

Engineered for flanged joints in tight-access offshore and process areas, where clearance is restricted and torque precision is non-negotiable.

FAQs

Select your required Torqueing tool as per specifications. Rest assured for the best hydraulic torque wrench quality and price.

Product Inquiry

Interested in Low Profile Ratchet, Hex. Type Hydraulic Torque Wrenches — THL Series? Get in touch!