torque-wrenches

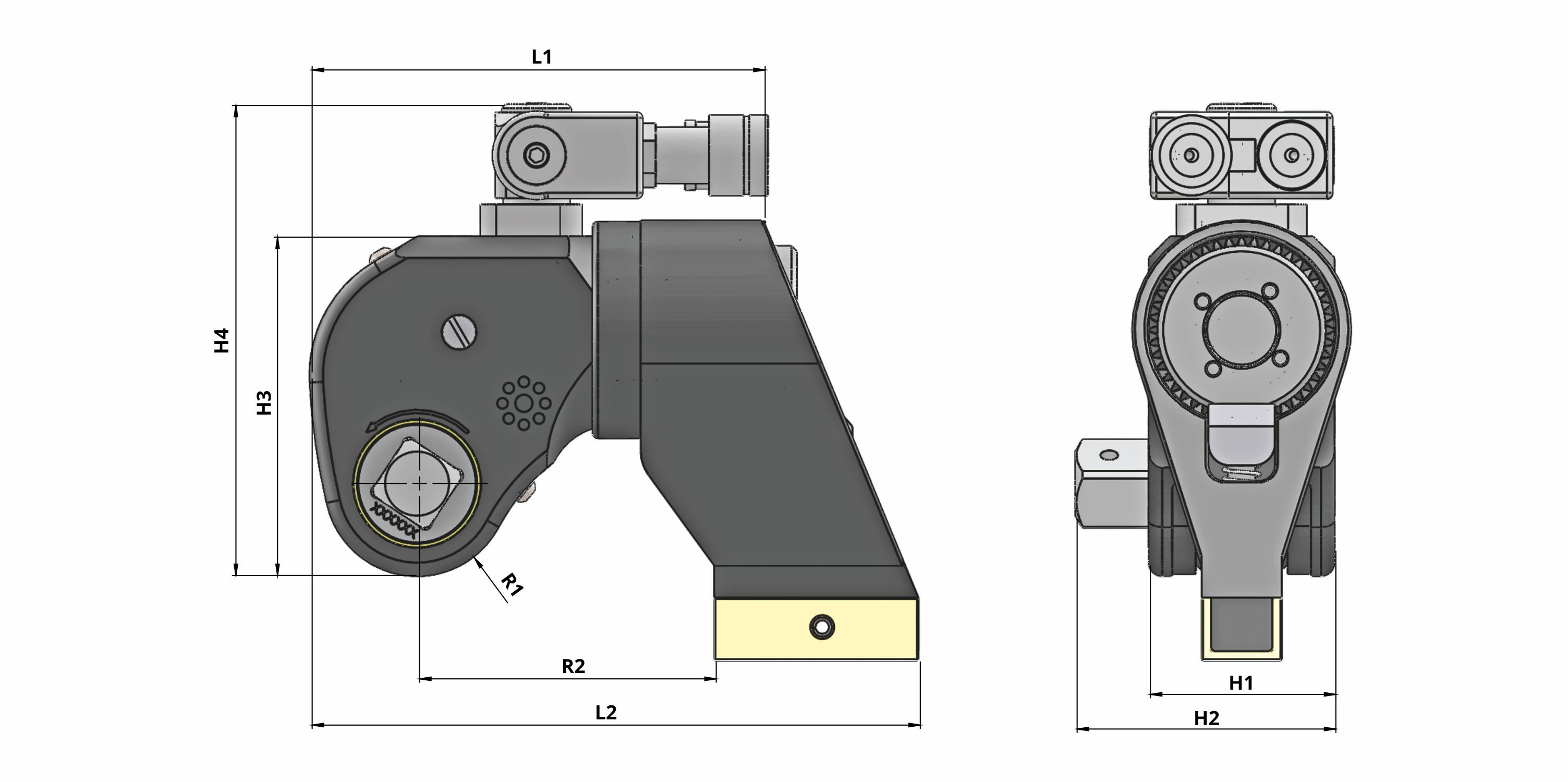

Square Drive Type

Engineered for high torque bolting applications, the TSL Series square drive hydraulic torque wrench delivers heavy-duty, reliable performance with precise torque control and reduced operator fatigue. Ideal for industrial assets, dry rentals, shutdown and turnaround projects, backed by Tritorc engineering, calibration, training, and service support.

Select model and view specifications

Engineered for performance in the most demanding industrial applications.

Compatible with a wide range of impact sockets, enabling efficient work across various bolt sizes and applications.

Built with aerospace-grade drive for extreme load resistance, ensuring reliability in high-torque, critical applications.

Push-through drive mechanism enables torqueing from one end and de-torqueing from the other, ensuring ease of operation with integrated handle.

Even in high-stress, high-pressure applications, the Tritorc tool design prevents leaks, maintaining steady pressure for consistent performance.

Smooth operation without locking, allowing faster, controlled bolting and de-bolting in high-torque environments.

On-tool torque reference reduces errors, ensuring compliance and accurate torque application during critical bolting tasks.

Every Tritorc hydraulic torque wrench is backed by comprehensive warranty coverage on all mechanical components.

Engineering team works closely with customers to design and deliver customized hydraulic torque solutions for unique requirements.

Professional onsite training and pre-commissioning services ensure teams are fully equipped to operate tools safely and efficiently.

Certified calibration services with traceability are available at purchase and recommended intervals for ongoing accuracy.

Complete torqueing systems including pumps, hoses, and sockets available for purchase or dry rental for quick mobilization.

Watch how professionals use the TSL

Explore other hydraulic torque solutions from our product line

Major energy company reduces downtime using TSL Series for critical subsea connections and wellhead assemblies.

Leading power generation facility achieves zero-defect bolting in turbine and generator casing assembly operations.

Our technical team is here to help you select the right tool for your application.

Contact Support →Trusted by professionals across critical industries worldwide

Don't see your industry? Our solutions are adaptable to any application.

View All Industries →Have questions about this product? Our team of experts is ready to help you find the right solution for your application.

Monday - Friday: 8:00 AM - 6:00 PM EST

Saturday - Sunday: Emergency Support Only