Built for demanding industrial applications, Tritorc's torque wrenches deliver are engineered for high-stakes industrial environments. Each tool delivers controlled torque with micron-level accuracy, repeatability, and safety under extreme conditions. No matter the job, or the challenge, our torque solutions ensure zero compromise, Every time, Every bolt!

Our TSL Series Hydraulic Torque Wrench aren’t just feature-rich; it’s purpose-built to solve your toughest bolting challenges—whether on-site or in-house. It addresses your real-world challenges and delivers measurable outcomes. With calibrated torque accuracy, high-strength drive components, and consistent cycle performance, it delivers results where it matters most.

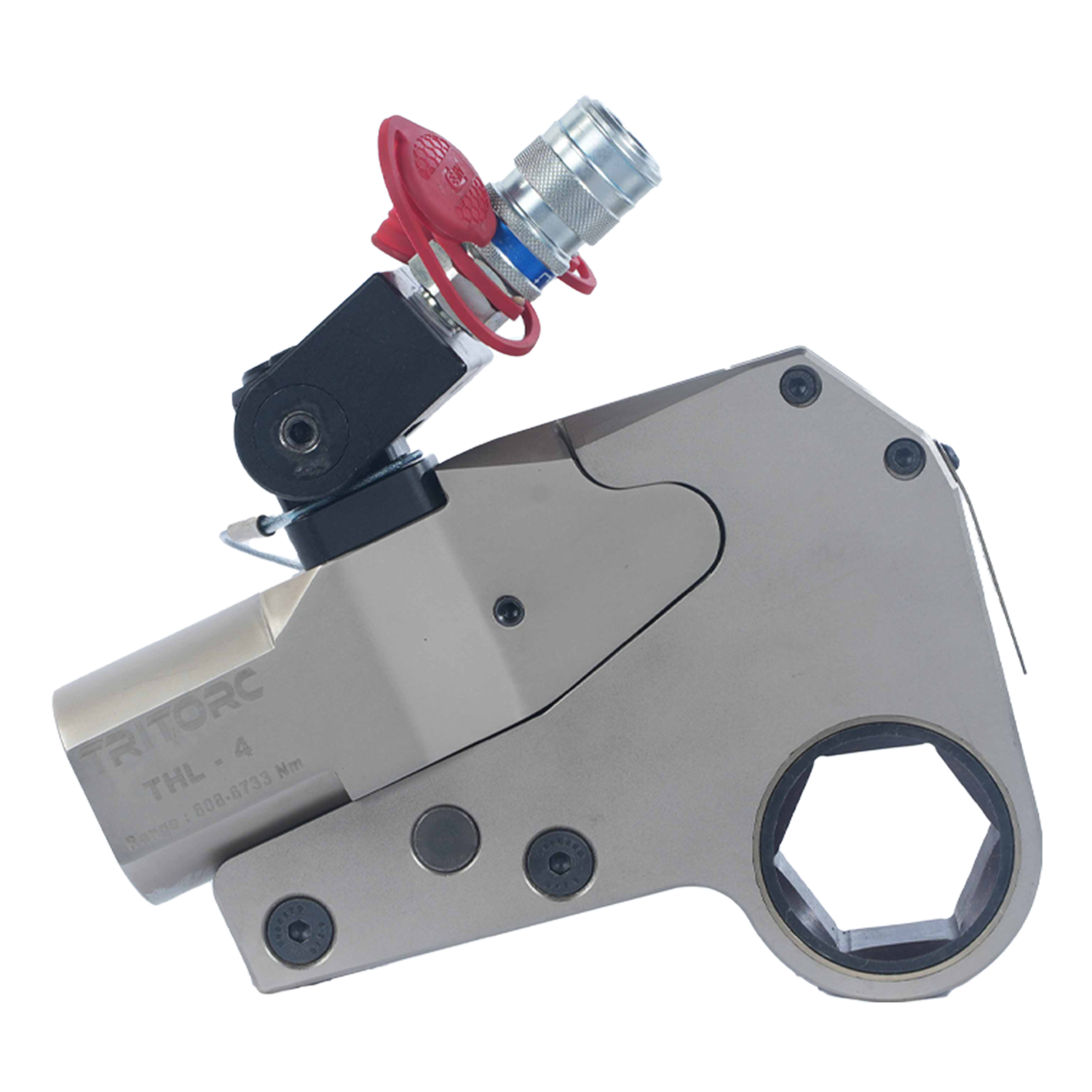

At Tritorc, we recognize that your bolting requirements demand more than just torque delivery; you need reliability, precision, and access in the tightest industrial spaces. The THL Series Low Profile He. Drive Hydraulic Torque Wrench is engineered to directly address these challenges and deliver operational improvements to your workflow.

In tight, hard-to-reach spaces, ordinary torque wrenches fall short. The THL Series Ultra Slim Hex Drive Hydraulic Torque Wrench is specifically crafted to excel where clearance is minimal but precision and power are non-negotiable. Its sleek design combined with robust torque capabilities ensures seamless operation even in the most confined industrial settings.

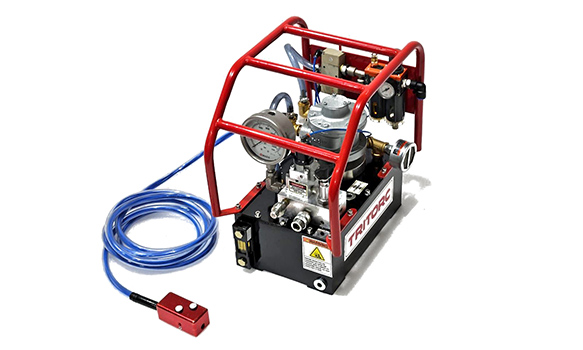

Engineered for high-demand industrial bolting environments, Tritorc's TWP-3 Pneumatic Driven Torqueing Pumps are purpose-built to power hydraulic torque wrenches through a compact, air-operated hydraulic system that ensures reliable pressure delivery, rapid cycling, and consistent torque output making it ideal for remote, hazardous, or power-restricted job sites.

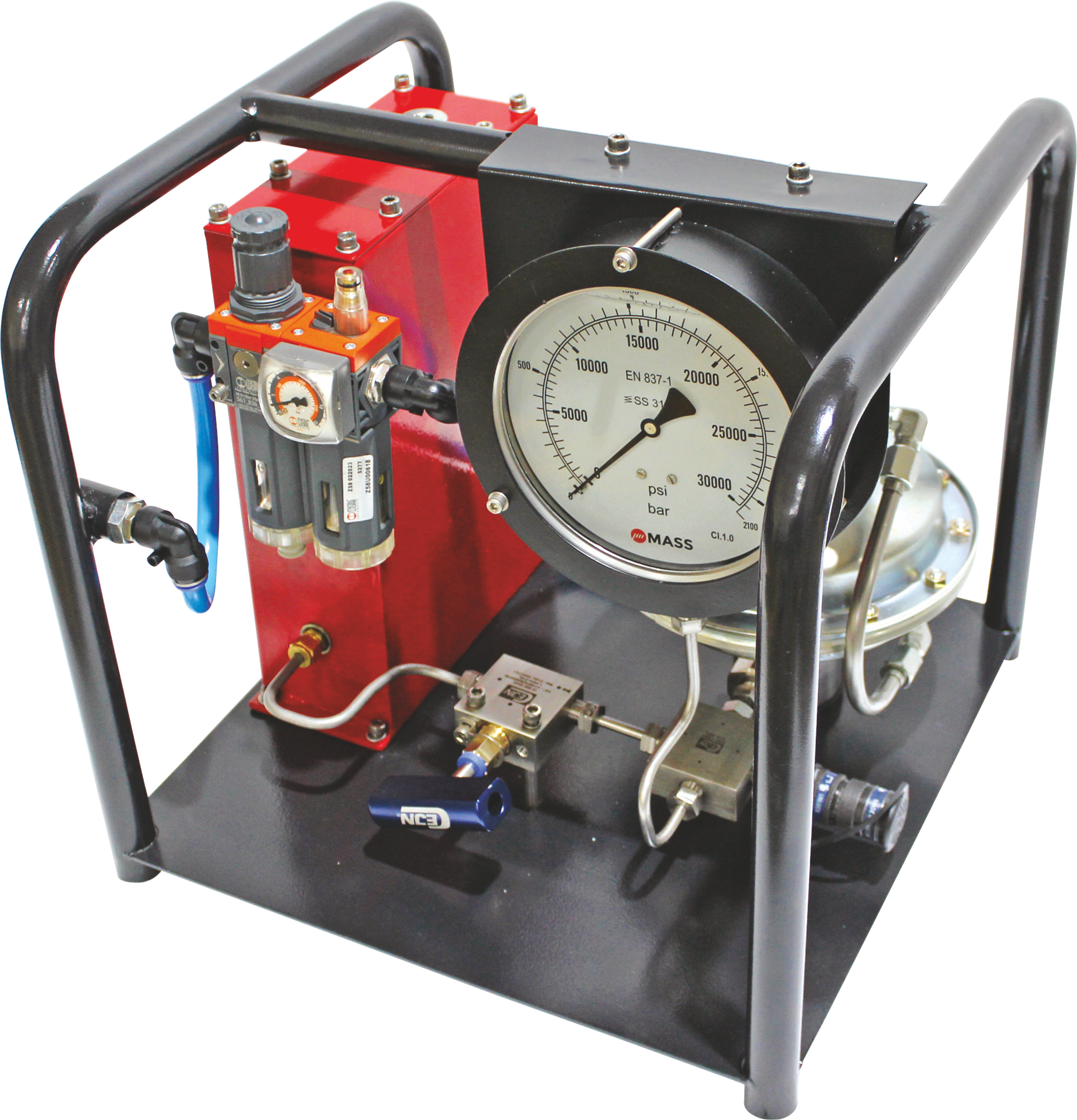

The TBP150 Pneumatic Bolt Tensioner Pump couples a compact, air-driven hydraulic system with 1,500 bar working pressure, delivering precise, consistent hydraulic output for high-pressure bolt tensioning operations where electrical tools are impractical or unsafe. Built for tough sites, it ensures fast setup, precise load control, and reliable performance in high-integrity bolting tasks.